Many have failed in the hunt for the arch-enemy of analog reproduction. Now Helmut Thiele is also targeting the tracking error angle – and wants to defeat it with a tricky tonearm. The test of his unique Thiele TT01/TA01 turntable/tonearm combination.

“Ah, I know that one!” As soon as Helmut Thiele had a coffee in his hand, he came across one of his own works in my living room: the beautiful Heco Direkt Einklang in dark gray. Design by Thiele, technology by Shandro Fischer (former head of development at Heco/Magnat) – a dream team of German loudspeaker construction. And a box that makes an incredibly strong visual statement with very discreet means. The only one here who regularly receives compliments from normal visitors. Yes, even from women.

Other Thiele designs are less exposed: The Thorens 1600 is currently running in the listening room – also entirely from Thiele’s pen. The direct-drive Magnat MTT990, which I recently set up again for a comparison? Logical: Thiele. The stylish and good Excalibur pickups, which the distributor TAD has established with great success as a house brand, and which I always like to install somewhere? Designed by Thiele in Duisburg. And these are just the things that spontaneously come to mind in my own environment. If you look a little further back, cult brands such as Acapella, Michaelson & Austin, Phonosophie and Phase Linear emerge, as well as former giants such as Pioneer.

So to say that Helmut Thiele brought me his first record player that morning is not without a certain humor. The TT01, however, is the first rotary that actually bears his name. A personal statement after a career spanning almost 50 years. He alone was the client, as well as the source of ideas. Of course, the construction was not created out of nothing. Thiele is familiar with all similar approaches, their strengths and weaknesses. There are many of them. The goal of building a record player without a tracking error angle is almost as old as the record itself. And it remains difficult.

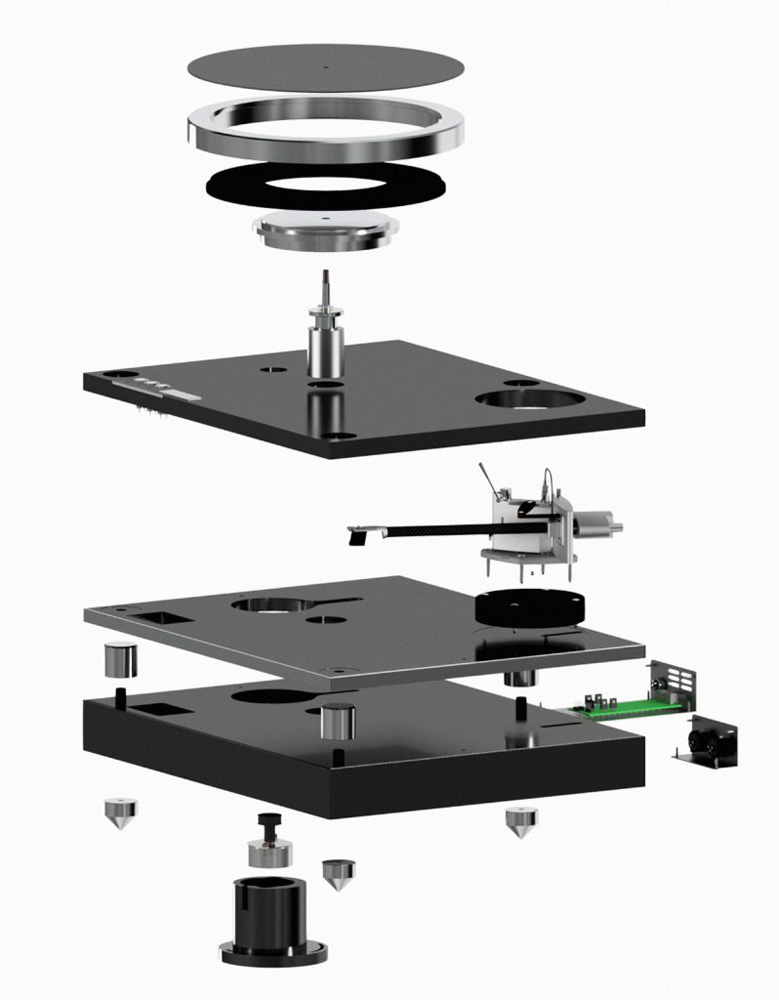

The special features of the Thiele TT01/TA01:

The problem of tracking misalignment results from a basic principle of record production: the stylus and stylus needle usually do not follow the same path across the record. It all starts with a cutting machine that engraves the sound vibrations into a soft layer of nitrocellulose: The lacquer master. The cutting stylus is reminiscent of the needle of a pickup, but has sharp edges that do not glide smoothly, but leave a precise track in the blank – and lift off a chip that is continuously sucked off. The spiral groove is created by the cutting head moving inwards by a fraction of a millimeter with each rotation. The feed rate is temporarily increased for empty grooves between the tracks, which is simple.

It is a real science, however, to always adjust the track width perfectly to the music during a piece: The more stereo content, the more bass and the louder the signal, the wider the necessary excursions will be. If the grooves are too close together, they can touch or even overlap, which would ruin the master. On the other hand, you don’t want to give away any space because the playing time per page suffers as a result. Modern cutting machines (where “modern” here means 1980s – no more were built after that) calculate the ideal feed rate dynamically with computer assistance. In any case, the journey of the cutting stylus – and later of the tonearm – over the side of the record is not as smooth and steady as it first appears. Rather, it is a sequence of accelerations and decelerations that are barely perceptible to the naked eye, but which represent real forces for the arm and pickup to follow. The movement is not even continuous from the outside in. This is because the officially permissible eccentricity of the plate – i.e. the deviation of the center hole from the geometrically perfect center that occurs during the pressing process – is already greater than the groove feed. Especially the real deviation with which our daily purchased LPs reach us: Even if we complain about the very blatant cases where the record wobbles so much that the pitch fluctuates by a quarter tone, we are still happy when the disc rotates with a deviation of perhaps half a millimeter. You can hardly see it when you put it on, and usually don’t hear it either.

From the arm’s point of view, however, this means work: for 20 minutes of music, an LP side has to rotate around itself 666,666 times. Even if the music is not black metal, by the way. In the course of these approximately 666 revolutions, the pickup crosses the recorded area of the LP, which – briefly measured – is 8.5 centimeters wide. The average feed per revolution in this example is therefore 8.5cm/666 or just under 130 micrometers. Even if we are very critical and take the old DIN as a basis, the permissible eccentricity of an LP would be 0.2 millimeters or 200 micrometers. In fact, the arm and system not only move steadily inwards by 130µm per revolution, but also wobble outwards by 135µm (eccentricity minus half the feed) and inwards by 265µm (eccentricity plus half the feed) each time. As I said, the real figures are likely to be higher in most cases.

But what’s the point of all this digression now? Above all, they show that the real requirements of a tonearm often differ significantly from the theoretical ones. Not all designs take these facts into account equally. Sometimes they are even – knowingly or inadvertently – ignored because one is completely fixated on another enemy of sound, the Moby Dick among the numerous analog problems: the tracking error angle. An inherent weakness of vinyl reproduction, which also drove Helmut Thiele to the drawing board (or rather to the CAD system) for his TA01 statement tonearm. The TT01 is merely the appropriate vehicle, the Pequod, with which Thiele sets sail on the hunt for the white vinyl whale. The TA-01 is the harpoon.

The tracking error is easy to explain, but difficult to avoid: The cutting machine guides its cutting head on a massive carriage, which is pushed over the panel radius by a powerful spindle drive. Similar to a lathe, which is also visible in the English term cutting lathe . First, the mastering engineer uses a microscope to check whether the graver is cutting straight into the nitrocellulose layer of the blank. And this alignment does not change because the cutting head then moves exactly parallel across the side of the panel. Unfortunately, tonearms usually don’t do that. You swivel the pickup along an arc of a circle. With a geometric trick – a defined inward crank – a rotating arm can therefore play two points of the recorded area exactly tangentially.

Before and after this, the pickup and needle – viewed from above – are always slightly twisted in one direction or the other in the groove. This misalignment causes distortions, and not even minor ones. Fortunately, most of these are low-order even harmonics. They do not make the sound bright, aggressive and poisonous, but at best stand out tonally with a little artificial warmth. But they also swallow up details, and as the groove circumference decreases – i.e. towards the middle of the LP – they become increasingly audible in a problematic way: as concrete uncleanliness, especially at high levels.

There are a few tried and tested tricks to get rid of the misalignment angle. For example, you can make the tonearm longer. In the limiting case of an infinitely long arm, you would have zero tracking angle – even without cranking, which would also cancel out the disruptive skating force. But this is a purely theoretical case. Even the 14- or 16-inch models that pop up from time to time look obscene and no longer fit anywhere. Practical approximations usually measure 12 inches instead of the usual 9 inches. This also results in significantly fewer errors, but also has disadvantages, which we were recently able to hear directly when testing the Acoustic Signature Tornado: The player came with two identically constructed arms that differed only in length, as well as identical pickups. In other words, a perfect experimental setup that is rarely found elsewhere. And on which I actually (and contrary to expectations) preferred the nine-incher in the long term.

Another approach is the tangential arm. Actually the perfect solution, because the pickup actually follows the exact path of the cutting stylus. However, the implementation is tricky: Some designs have a kind of tonearm slide on rollers and rails over the record. This means sensitive, exposed running surfaces and many bearings with play and/or friction. Others allow the carriage to glide on air cushions and thus virtually eliminate friction, but require compressors, filters and all sorts of less attractive hoses. Others actively assist the sled with an electric drive. This requires a sensitive control system that follows the constant movements of the plate in a flash before they pull on the needle on one side and jeopardize the sacred balance of forces around the diamond.

I’m really dispassionate about it, but I wouldn’t want to use most of these arms on a daily basis. At best, because the handling is a little more complicated. Perhaps also because of prohibitive prices. I don’t mean the 24,000 euros for the Thiele TT01/TA01, but really prohibitive prices. In less favorable cases, however, also due to obvious weaknesses. Be it in the reduction of resonances, in the handling of wavy panels, due to a design that is out of touch with practice or complex control systems that get out of control late at night. What’s the point of slaying Moby Dick if the ship sinks in the process?

The Thiele solution

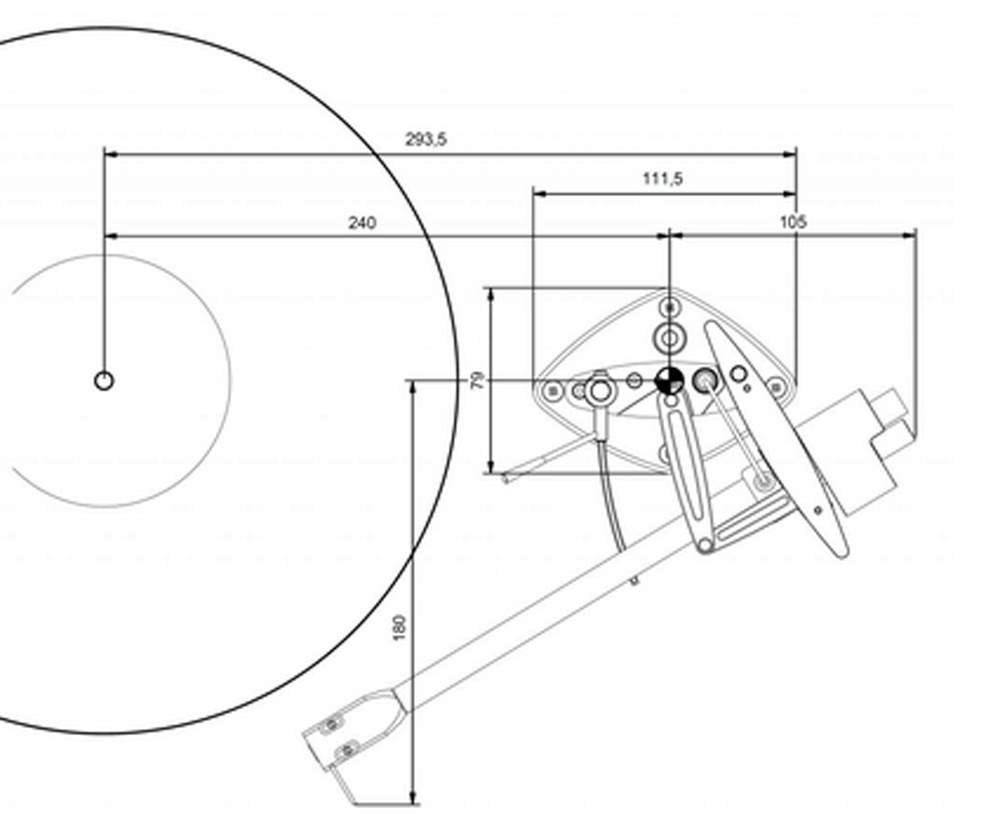

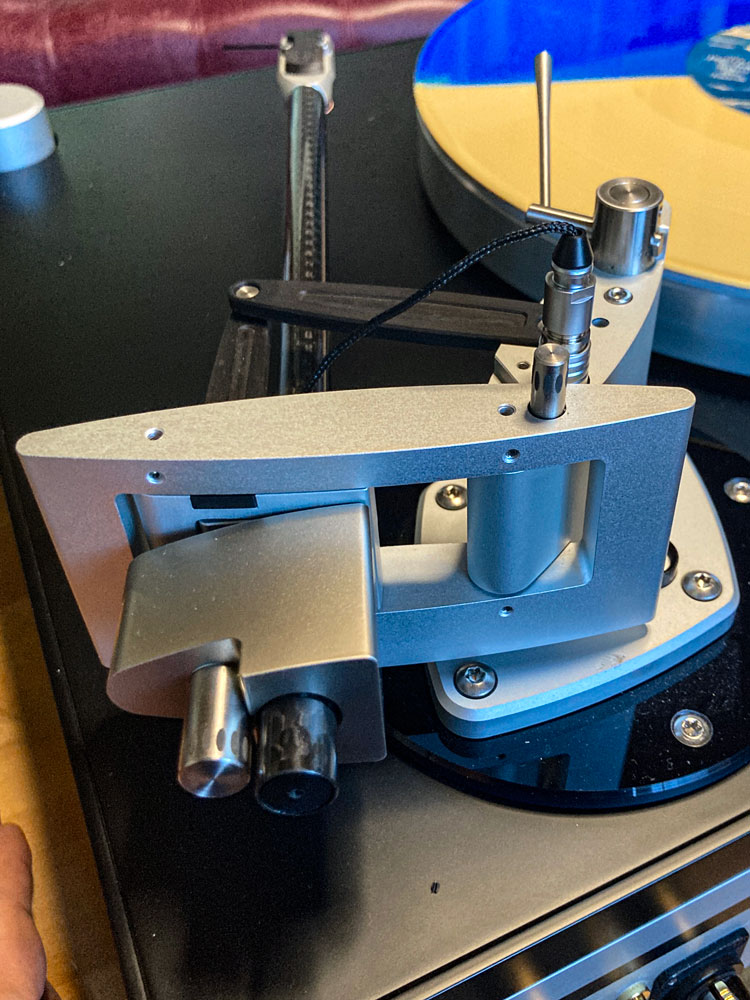

Helmut Thiele’s approach is already visually pleasing: it looks like a normal rotating tonearm with an extravagantly shaped bearing. Or rather two. Or no: three? Industrial designer Thiele has brought a lot of function into a clear, elegant form. It is only when you get closer to the arm that you notice how differently it moves. The TA01 actually rotates around two points horizontally (it works normally vertically). It basically performs two circular movements that overlap in such a way that the headshell always floats parallel above the grooves at every point on the record. This is reminiscent of the swivel mimics of certain kitchen furniture or the multi-link wheel suspensions of modern cars. The wheel can deflect as far as it wants without changing the camber. Here, the arm swivels over the plate and is exactly tangential to the groove for every millimeter of its journey. Tracking error angle: zero. Or for pedants: a maximum of 0.036 degrees. From the lead-in to the end groove. Now the whole thing just has to work.

And it works well, surprisingly well in fact. This does not mean that the arm does not require any adjustment or retraining. The “tonearm hand” – in my case the right one – has learned over decades how the arm tube and headshell follow their guide from the parking lot to the beginning of the record. A simple swivel. The Thiele arm, on the other hand, not only moves inwards, but also forwards at the same time. This is because the arm bearing sits at the end of a short, solid swivel arm. The two arm sections are coupled: how much movement inwards corresponds to which movement forwards is determined by a slender ebony guide rod, also mounted on ball bearings. This has an initially surprising side effect: although the headshell is straight as a die, this arm also generates skating forces during operation. Each pull on the arm tube in the axial direction results in a proportional pull towards the center of the plate due to the arrangement of the two bearings. So also the friction of the needle in the groove.

To compensate for the skating force, Helmut Thiele uses the mass of the bearing block and the arm itself. The center of gravity of this assembly is outside the pivot point. If the axis of rotation is tilted only minimally, the mass continues to move downhill – even if the “mountain” is only a few hundredths of a meter high. The arm base sits on a central bearing ball for free movement in all directions, while four adjusting screws on the outside tighten it firmly and at the same time allow the most sensitive position changes. During production in Duisburg, Thiele first calibrates the arm and only then inserts a super-precise circular spirit level at the base. Later, you only need to position the player exactly (really exactly!) horizontally. The exact alignment of arm and drive is critical: deviations that you wouldn’t even recognize with the usual cheap vials can already impair the function here. Which is why I can’t agree with those colleagues who have described the TT01 as uncomplicated: You don’t move this player to the side for a moment or even move it from its regular place to somewhere else – even if it’s just to get to a cable. It should also not be operated on floors that “work” in any way: Concrete and top furniture or a first-class wall bracket are mandatory.

The material and finish of the arm are of the finest quality: accurately milled, blasted aluminum characterizes the base and bearing housing. They contain the finest ball bearings currently available, which Thiele nevertheless selects and refurbishes before installation. Zero play is a top priority for an arm with so many moving parts. But also smooth running, which the developer tests with precisely measured pieces of paper in the milligram range. And low resonance, which is noticeably and audibly sensationally good in the TT01. Also because the arm tube consists of two coaxially arranged carbon fiber tubes rather than one. Thiele fills the space between the tubes with a damping gel in a tricky process – at this point at the latest, ordinary carbon arms let their headshells hang bashfully. Incidentally, the TA01 consists of an aluminum and ebony sandwich and is adjustable in azimuth.

The tone arm height can also be adjusted – even very conveniently during operation. Very dedicated users can also pull the entire arm upwards with two hand movements and replace it with a second, pre-adjusted one: an expensive but uncompromising way to quickly switch to a different pickup.

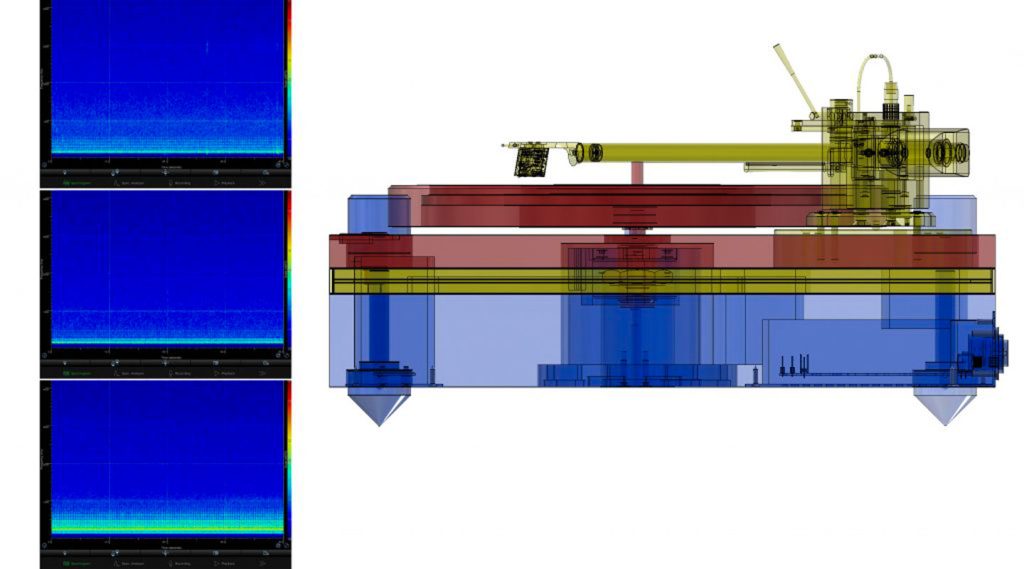

The turntable carries the spectacular arm with elegant understatement: a three-layer chassis made of different woods and wood composites provides separate platforms for the motor and electronics, the tonearm and the platter bearing. The feet can be adjusted very sensitively from above (thank goodness!), and the large linear power supply unit has been outsourced to minimize interference. The plate is also in three parts, with an outer and inner part made of aluminum and an acrylic ring in between – and everything is so tightly tolerated that once it is put together, it can only be taken apart again with force.

What the TT01 lacks is a hood. As a consolation, a beautiful, professional flight case comes as standard for transportation. My test specimen emerged from this box with a pre-mounted pickup, which I left mounted for the time being because of its fantastic sound. It’s Helmut’s system, so I don’t care about the cost per operating hour. And for the Ortofon Verismo, at a new price of 7,000 euros, these are not for the faint-hearted. After a few pages of records, it was clear to me that the Edel MC really fits perfectly here, and it plays in top form on the TA01.

Hearing test

The stability of the Thiele sound is breathtaking: no matter whether singer-songwriter, big band or studio rock epic: my Tannoys always painted a wide, spacious picture in which musicians move in a completely relaxed manner or – depending on the situation – sit precisely in their place. Before I dig out my notes on any jazz trumpeters, I can think of a recording that is usually even more difficult to access: the brittle, nervous, claustrophobic “The Apple Drop” by the US post-punk band Liars.

Liars are one of those bands that you know straight away are brilliant, that you have to own their records and celebrate them. However, it quickly becomes clear that you will rarely have the necessary mood and stability to endure more than one or two tracks. A love-hate relationship that has spanned ten cherished but rarely heard albums since the first album “They Threw Us All In A Trench And Stuck A Monument On Top”. And very slowly you do become a fan – or much faster if you run a TT01. With this, the dissonant component in the pieces recedes somewhat and the hypnotic rhythm and vocal parts begin to make sense. The music that colleagues like to call “Uneasy Listening” becomes noticeably easier.

The music of Sufjan Stevens is much less bulky, but more challenging in its opulence, oscillating within an album between intimate singer-songwriter arrangements and multi-layered choral and orchestral freak-outs. “Mars”, from the album “Planetarium” (2017, 4AD – 4AD0009LP) opens up huge spaces over seven minutes, with a brass-heavy middle section and an enchantingly delicate choral finale.

Difficult material, which the TT01 presents in all its playfulness and grandeur. And without subtly but successively condensing the recording in the beginning last third of the side, as even the distinguished Thorens TD 1600 with TP 160 cannot completely prevent. Well, it only costs a fifth. And in details – the speed buttons of the drive, the external power supply and the connection panel – it is even reminiscent of its big half-brother. For his masterpiece TT01, however, Helmut Thiele relies exclusively on symmetrical cabling. Owners of phono preamps with RCA inputs will have to make do with adapters. Or just buy a suitable preamp at the same time. It is worth it. In our test, top MCs benefited from the balanced connection, and the decision in favor of the TT01 is likely to be a permanent one. This is supported by power, stability, great dynamics and a clarity that is unusually well maintained right to the end of the record side thanks to tangential scanning.

Conclusion Thiele TT01/TA01

If Helmut Thiele’s plan was to combine tangential scanning with the low maintenance and convenience of a classic rotating tonearm, he was only partially successful. The TA01 is not an undemanding workhorse in the sense of a Technics or Linn turntable – not even the Thorens TP 160 developed by Thiele himself. The only arm bearing Thiele’s name is a little capricious, requiring patience during assembly and a steady hand during operation. The sound potential of the arm and the entire player feels like a racing car compared to an all-wheel drive SUV. Or to put it another way: it doesn’t get much better than this.

Rating

Sound QualityUsabilityBuild QualitySummary |

| The rating always refers to the respective price category. |

| | Large-format, highly dynamic sound |

| | Sophisticated tangential arm with a perfect finish |

| | Visually inconspicuous, exceptionally quiet and stable drive |

| | Arm setup requires a lot of feeling, clean placement requires some practice |

Distribution:

AUDIO-TRADE Hi-Fi Vertriebsgesellschaft mbH

Wallufer Street 2

D-65343 Eltville am Rhein

www.audiotra.de

Price (manufacturer’s recommendation):

Thiele TT01/TA01: 24,000 euros (without pickup)

Thiele TA01 tonearm: 11,500 euros

| Thiele TT01/TA01 | |

|---|---|

| Concept: | Belt drive with tangential-style tonearm |

| Chassis: | 3-layer construction made from different types of wood |

| Outputs: | 1 x balanced (XLR) |

| Power supply unit: | external |

| Speeds: | 33.3 rpm and 45 rpm |

| Special feature: | Rotary tonearm (TA01) without tracking angle |

| Dimensions (W x H x D): | 51.0 x 20.0 x 40.0 cm |

| Weight: | 17.0 kilo |

| All technical data | |