You drive and drive and drive. And drive. And at some point, when you think you’ve reached the end of the world (at least the end of the European Union), the Slovakian town of Prešov appears – 800 kilometers east of Dresden and 150 kilometers west of Ukraine. I had never heard of this little town before and had to realize right after arriving that the term “little town” is probably out of place. Prešov has a charming historic center, just under 100,000 very nice inhabitants and is the second largest city in eastern Slovakia. Slovakia is certainly more often underestimated. Or did you know that more cars are produced there than in Italy? Or did you know – now we come to the real point – that here, located just before the Ukraine, is one of the most modern and productive HiFi forges in Europe? But that’s exactly how it is. Canor is at home here!

You think it’s just a small but ingenious tube factory? I thought so too. The tube units in the tests were all outstandingly good and meticulously crafted, but I only found out on site that there was such a big company behind them. Because in addition to the fine Canor tube components, all of Pro-Ject’s electronic components are also made here, for example. And those from IsoTek and Musical Fidelity. And several others as well. And all this with a vertical range of manufacture that leaves visitors in awe.

Production is divided between two locations: The “large” production building offers more than 3,000 square meters of space spread over several floors. There are still reserves here for further growth; an additional 5,000 square meters have been sublet. And there is the development building, located a few hundred meters further on. In addition to the development department, the assembly line for SMD boards is also located there. But more on that later.

Canor: the production

Everything starts with huge aluminum plates. Even their delivery must be a show – simply because they are so heavy. These plates are then cut to the required dimensions, machined, colored (anodized) and then fitted with the electronic components. The short tour through the production process shows how this is done.

After the panels have been cut to a manageable size, they go into the metal milling machine, where – at least in this case – they are milled into fronts for the Pro-Ject Phonobox S3:

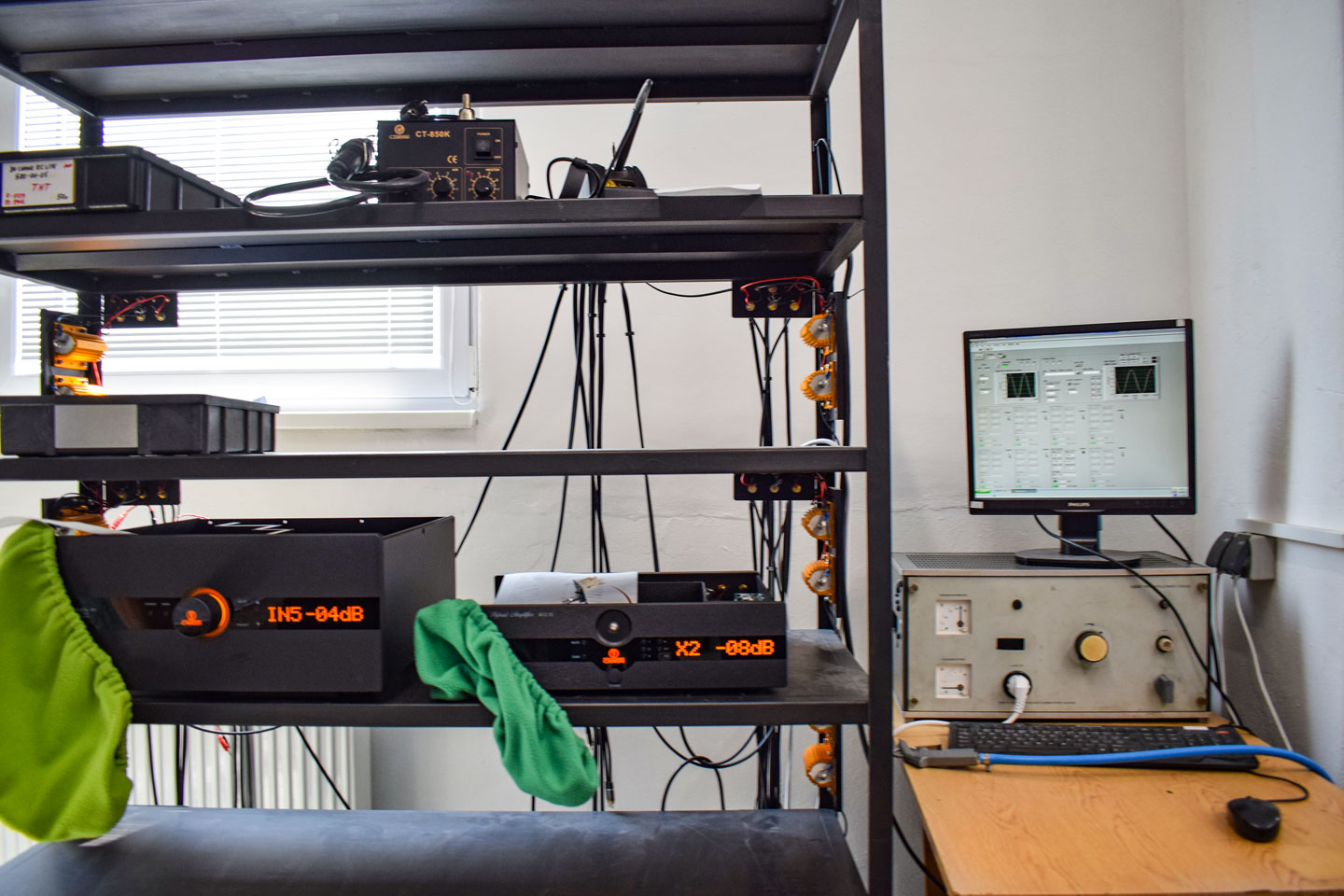

After being precisely cut in the metal milling machine, the individual metal parts take a bath. The Slovaks use the process of anodizing to color the metal parts in silver or black. As a reminder, anodic oxidation creates a firmly adhering layer of color on the surface. And because the Canor makers did not receive a suitable offer of this work, they simply developed the PC-monitored anodizing bath themselves. The thoroughly impressive bath fills an entire room of the industrial building and is in permanent use. No wonder, because coloring takes time: 2 hours for black, 1.5 hours for silver. With the number of hundreds of metal parts per day, you can calculate the time required…

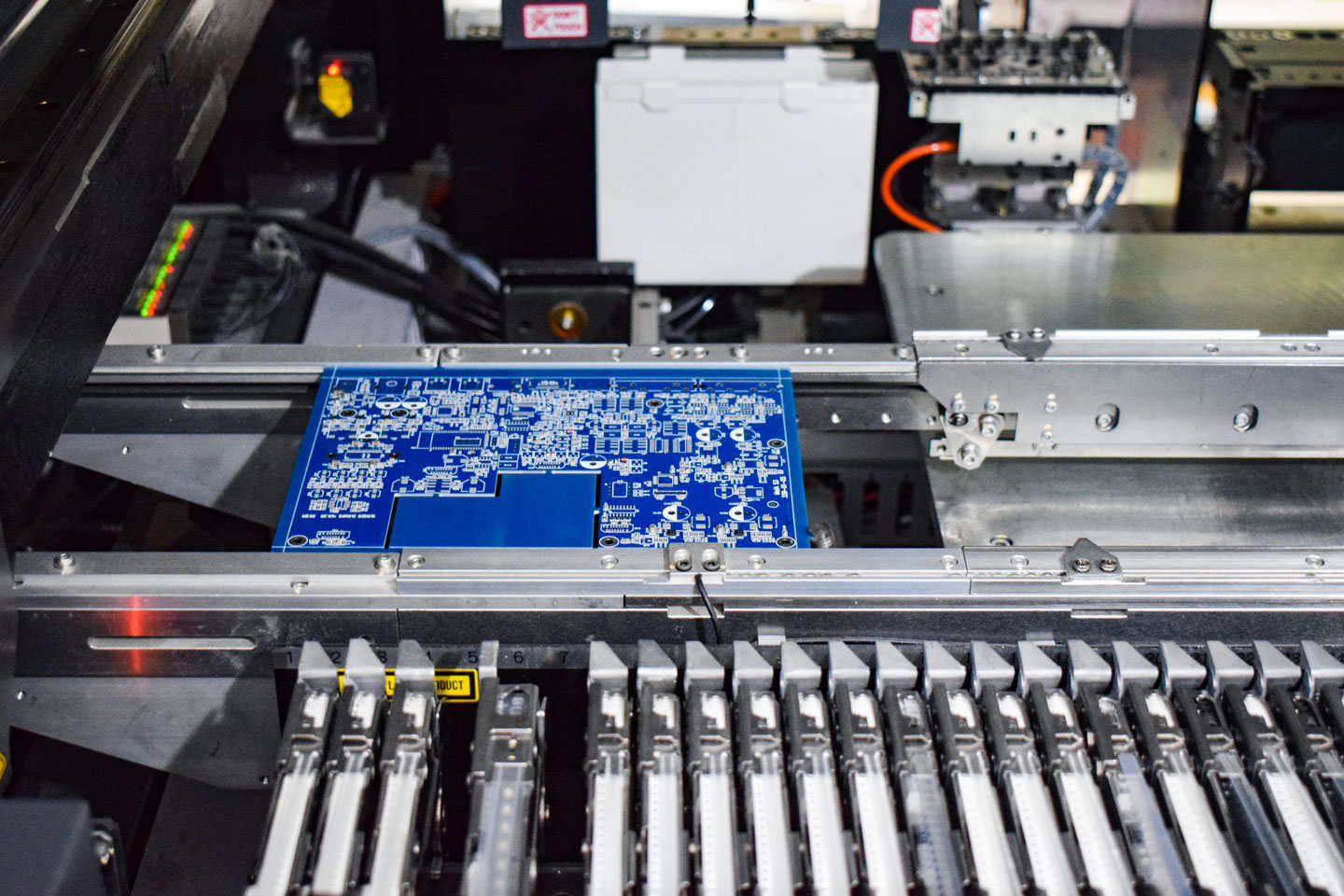

Once the housings are finished, the electronic innards are added. Most of the boards are SMD-equipped. The extremely short signal paths of the miniaturized components have predominant advantages in terms of sound. The SMD assembly line is also very impressive. After all, I’ve also been to Linn and to Burmester – Canor’s is significantly larger:

I am told a dizzying number when asked: 40,000 components are placed on the boards here per hour. It would take a bit longer to do that by hand…

But the boards are still not finished after the inspection. Now comes the ennoblement of the whole thing: the soldering bath, which electrically connects the components to each other:

Here I draw a short interim conclusion: I had never seen a production with such a vertical range of manufacture in my 30 years as an editor. Everything down to the cheapest Pro-Ject components is manufactured here with the same precision and under meticulously clean circumstances. And in much higher quantities than I would have thought.

The actual production…

…is then done by hand. Most of the 87 employees work in production. Hundreds of components are produced here every day. Naturally, I wanted to know more. But Marketing Manager Ivan Bosnovic didn’t want to commit himself: “I can’t give the exact number. But there are several tens of thousands per year. And we can do quite a bit more…”

The working atmosphere is concentrated, but very relaxed. In the front part of the production hall, Pro-Ject and Canor components are built side by side. But then there’s also a small hall where Musical Fidelity’s electronics are being created. But the largest part is occupied by IsoTek.

IsoTek

Canor is a hi-fi manufacturer of noble tube electronics under this name but lives mainly from the OEM business. The name Pro-Ject has already been mentioned: The Slovaks manufacture all the electronics, but the brand itself is owned by Austrian audio tuning boss Heinz Lichtenegger. I was really surprised by the volume (or rather the high quantities) of Pro-Ject electronics. Likewise, by the IsoTek production, which is also done here. The world market leader in terms of current filtering has experienced a fabulous upswing in recent years. Canor has probably played its part with its high-precision manufacturing. In any case, IsoTek occupies half of the production area and large floor space for storage.

Where the audiophile approach is particularly visible

After a good four hours, I thought I had seen everything – and was already seriously impressed. But the highlight was yet to come. Or rather, several highlights. I was particularly impressed by the handling of the tubes, which are not only pre-aged at Canor, but also precisely measured and selected in pairs:

Because Canor makes a record of each tube and also notes which tube is installed in which amplifier, the quality is maintained even when tubes are replaced. The customer talks to his dealer, who then orders tubes from Canor whose parameters are exactly the same as the tubes originally installed. Incidentally, this process applies to both power and preamp tubes.

But that’s not all: after a Canor component has been created, it first goes to the so-called burning station. There, each device must “stew” at 250 volts for 48 hours. If there are any electrical weaknesses, they are usually already detected here.

Then an experienced Canor employee checks all the functions – right down to adjusting the phono stages – what an effort!

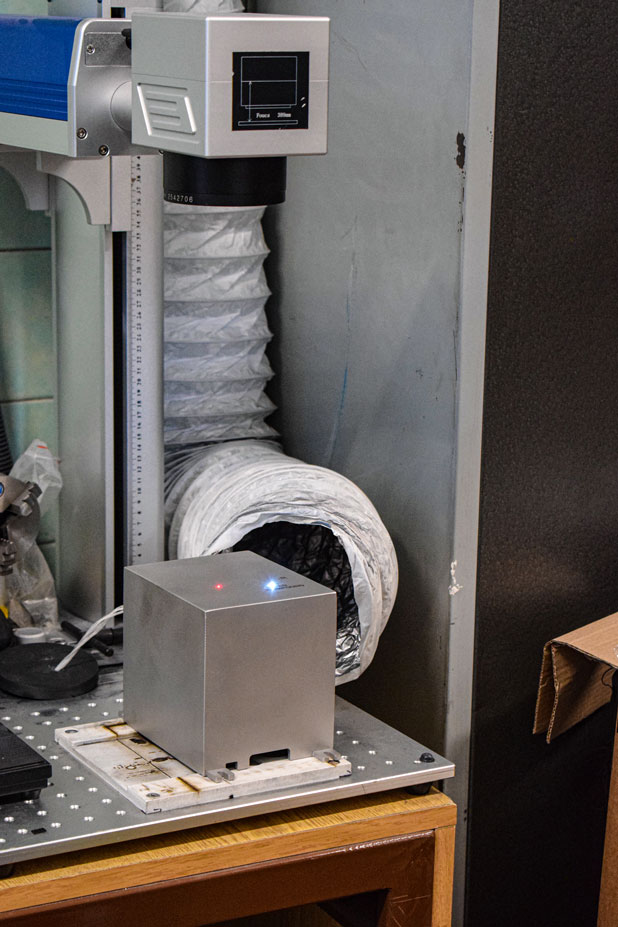

And then there is the torture chamber. In a completely anechoic room, the amplifiers are then tortured to blazing heat to see if any weak points are present. I repeat myself: what an effort.

The development department…

…at Canor is quite large. For a “small tube company”, there are a surprisingly large number of engineers working here. Maybe the Slovaks do not only develop circuits for their tube electronics…

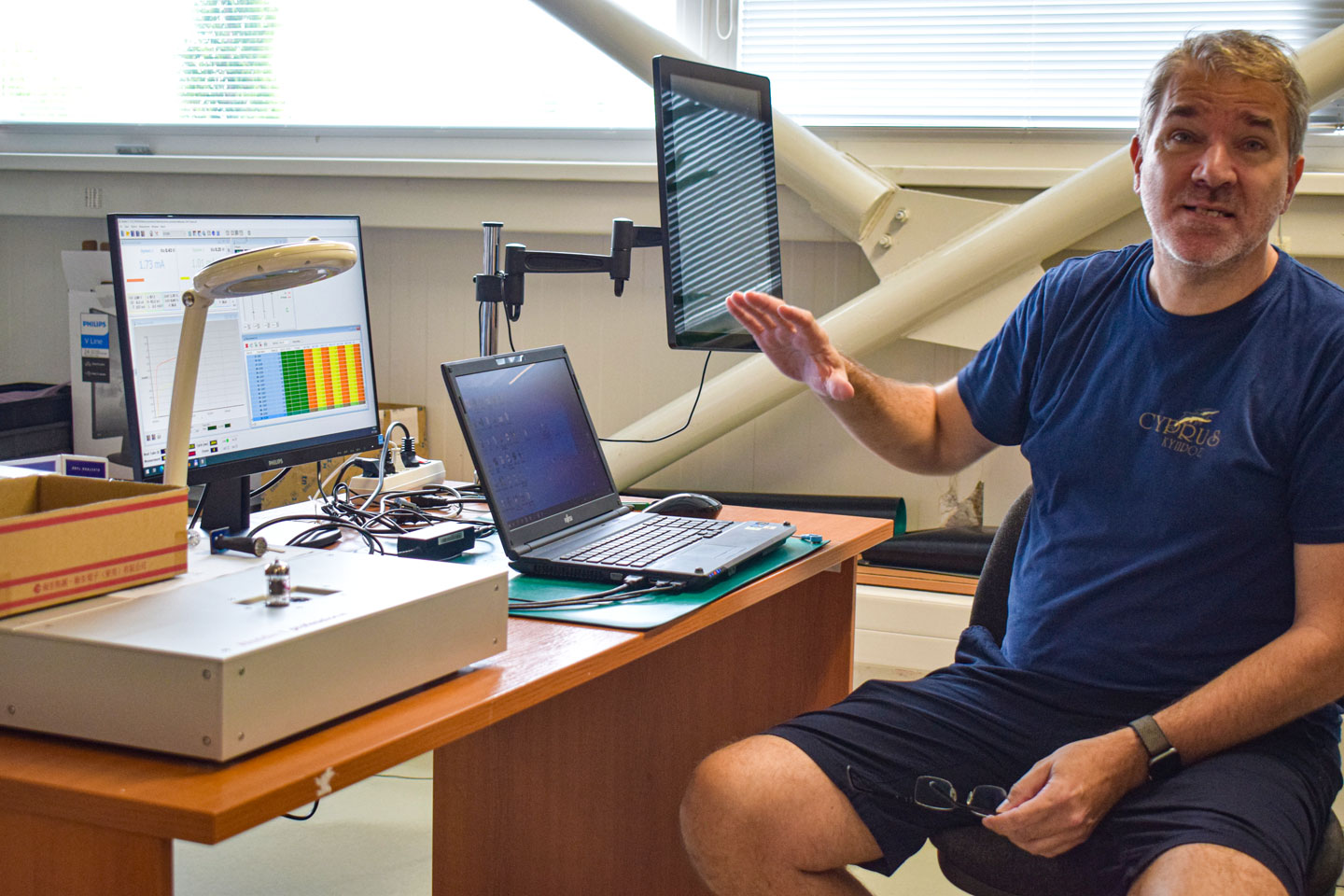

I was really surprised when John Westlake suddenly appeared from an office. Although, according to legend, he does not have a single degree from any technical college, John Westlake is one of the brightest hi-fi developers of our time. For many years, he played a key role in shaping the electronics components of Audiolab, Leak and Quad for the Chinese IAG Group – all of which are extremely capable and hugely award-worthy hi-fi.

But a short time ago, the Canor managers were able to convince the likeable (and blessed with a lot of British humor) hi-fi globetrotter to now let his flashes of inspiration shine in Prešov. And Westlake got right on it: The new Virtus A3 all-in-one integrated amplifier (probable price: 5,900 euros) was probably created primarily on Westlake’s thought framework. In any case, during my visit he chatted blithely about the merits of the old Quad-405 power amplifiers, which are also built into the Virtus A3 in a very similar (though much more modern) form. The circuitry trickily combines Class-A with Class-D.

In addition, the A3 combines – rare in an integrated amplifier of this class – a high-quality DAC with a phono stage of at least equal quality. As usual with Canor, you can adjust the pickups, but in this case the control knob speaks to the user. Not only does it have a small display that provides information, but also the movement mimic of a mouse, which can be used to control all sorts of things. You can almost feel Westlake’s inventiveness here. Of course, I immediately ordered a A3 for testing and I’m already looking forward to its arrival…

Conclusion

Perhaps it was already to be taken from my lines: When I left, I would not have thought to find such a professional factory with so much development competence and high-end consistency in Prešov. In short: I am still impressed. With the love with which the components are manufactured here, but above all with the enormous vertical range of manufacture, the Slovaks are unquestionably setting standards.

| Canor in numbers | |

|---|---|

| Location: | Prešov / Slowakei |

| Foundet: | 2000, from 2008 under the name Canor |

| Employees: | 87 |

| Production area: | >3.000 qm |

| Headquarter: | 1.200 qm |

| Main OEM brands: | IsoTec, Pro-Ject; Musical Fidelity |

| Special feature: | Extreme vertical range of manufacture |

| Developer: | Zdenek Brezovjak, John Westlake, |

| Owners: | Zdenek Brezovjak (Chef-Ingenieur), Jan Kosco (Vorstandsvorsitzender), Jozef Curlik |

| Alle technischen Daten | |

More from Canor:

Test Vor-/Endstufen-Kombination Canor Hyperion P1 + Virtus M1

Test Röhrenvollverstärker Canor AI 1.10: besser gehts kaum

Test Canor PH 2.10: Top-Phono-Vorverstärker mit Röhren-Boost

Test Phonostufe Canor PH 1.10: dem Himmel so nah

Test Vollverstärker Canor AI 2.10: volle Kraft mit Röhre

Test Canor CD 1.10: CD-Player mit feinem Röhren-Sound